Every user has had trouble with a scratched CD. In the case of data CDs (CD-ROM), the drive cannot properly read the CD, giving rise to reading errors. In the case of audio CDs, the CD skips when we play it.

The first thing to do when coming across a CD with a read error is to clean it, to check whether it the error is not being caused by a dirty surface. You can even wash the CD gently with a little detergent, using your fingers to clean it (avoid sponges, since they can scratch the CD). If the error persists, try reading or playing the CD on another drive. If another drive (or CD player, in the case of audio CDs) gives the same result (read error or skipping, in the case of audio CDs), it will mean that the CD is scratched.

Looking against the light, the recording surface (the flip side of the label) of a CD with this kind of trouble will allow you to easily see one or more existing scratches. A CD's data is recorded on a metal layer inside it, a silvered layer on commercial CDs, which is usually golden on CD-Rs. This metal layer is inset in a transparent plastic covering (polycarbonate), used to protect the CD's metal layer and allow printing a label on the side not used for reading.

A CD-ROM drive or CD player utilizes a laser beam to read the metal layer. This laser beam crosses the plastic layer and reads the metal layer. If the plastic layer is scratched, the beam will be unable to pass through it, resulting in a read error or skipping the music. In other words, the data to be read are still in the CD, the trouble lies in the layer of plastic.

As the CD's contents are preserved, a scratched CD can be recovered by polishing its plastic surface. If, after carrying out the above cleansing, the CD persists in giving reading errors, just polish the CD with toothpaste. That's right, toothpaste. It works wonders, and you won't spend a fortune buying professional cleaning kits. Polish the scratches with a cotton swab, rubbing gently the paste-imbued swab over the scratches until they disappear or until you notice that you have removed them as far as possible. Sometimes the paste may cause new scratching, but it will be merely superficial and easily removed. After clearing the scratches, wash the CD in water.

If there are still scratches that the toothpaste has not managed to removed, use a metal polish (Brasso) in the same way as described above. Finally, rub Vaseline on the CD, very gently (do not press hard), from moving out from the centre to the rim.

The last step will be testing the CD. If it starts working properly, great. If not, repeat the above procedure, looking for the scratch that is causing the error and concentrating your polishing efforts on it.

Friday, September 29, 2006

GET DATA FROM THE SCRACHED CD

Posted by M. ARUN REDDY 0 comments

Monday, September 04, 2006

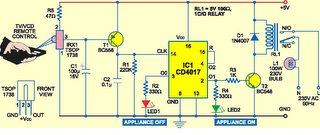

CONTROL FAN, LIGHT, AND MANY MORE IN HOME USING UR TV OR VCR OR DVD REMOTE CONTROL

Posted by M. ARUN REDDY 0 comments

ELECTRONICS ITS REALLY COOL

Clap Switch

Several circuits for sound operated switches have been published earlier. The circuit shown here for clap operated switch is inexpensive and easy to assemble by hobbyists of any level. Clap sound signals picked up by condenser microphone are first amplified by transistor T1, which is a simple common-emitter amplifier. Amplified signals are rectified by diode D1. Positive half cycle of clap signal is applied to a 3-stage DC amplifier formed by transistors T2, T3 and T4. Output from transistor T4 is used as a clock for flip-flop IC1 (7472). For each clap, the output of IC 7472 toggles alternately to on/off state.

Transistor T5 functions as relay driver since output level of IC1 is insufficient to drive a relay directly. The entire circuit, except the relay driver, operates at 5 volts regulated. The 5-volt supply is derived from 12V supply (used for relay driver transistor T5) using a zener diode with series resistor R11 (150-ohm, 1-watt). Using this circuit any electrical or electronic load can be controlled by just clapping in front of the microphone. The microphone should be housed inside a suitable funnel shaped enclosure to improve sensitivity. Potmeter VR1 is used as sensitivity control.

The entire circuit can be powered from simple 12-volt unregulated supply using 12-volt step-down transformer, followed by full-wave rectifier and a filter capacitor of about 1000µF, 25V.

Posted by M. ARUN REDDY 0 comments

property calculator

COLLEGE TOOLBAR

| toolbar powered by Conduit |

Connect this circuit to any of your home appliances (lamp, fan, radio, etc) to make the appliance turn

Connect this circuit to any of your home appliances (lamp, fan, radio, etc) to make the appliance turn